CONVEYOR DRYERS

Our dryers come in four basic formats - and can be custom built to meet your dimension and drying needs.

Product enters and exits at opposite ends

Standard airflow is upward, downward airflow is optional for certain products

Models can be all, heat, all cool, or a combination of both

Optional airflow recycling (internally or externally)

Product depth of 2” to 12”

Highest air pressure is placed against wettest product at inlet end for best drying performance

Width 2’ to 8’ and Length 12’ to 50’ or more

SINGLE PASS DRYERS

TWO-PASS DRYERS

Multiple pass design increases air to product contact for improved efficiency

Product enters and exits at the same end of the system

Product is mixed as it drops into the proceeding pass for increased moisture uniformity

Standard airflow is upward

Models can be all heat, all cool, or a combination of heat and cool

Each convener is driven independently; product depth can be adjusted to compensate for product shrinkage, improve efficiency, and increases dwell time

Two pass design increases drying area without depleting floor space

Standard controls adjust airflow, product depth, dwell time, and air temperature

Product depth from 2” to 12”

Width 2’ to 8’ and Length 12’ to 50’ or more

MULTI-STAGE DRYERS

Connect any amount of single-stage models together to create a custom multi-pass and multi-stage configuration

Connection can be made in-line, stacked or in parallel

Custom connection helps meet unusual or difficult floor spaces and layouts

Easy to upgrade the capacity and efficiency of any existing drying system by adding an additional model

NEGATIVE AIR DRYERS AND COOLERS

Single or multiple pass available

Fan (cyclone on air outlet side only, for negative airflow though entire system

Ambient air cooling and/or convection drying with steam heat exchanges

Airflow upward or optional downward airflow on top pass of two-pass designs

Lower height profile designs for reduced head space areas

Standard fines removal of bottom flat floor

FEATURES & OPTIONS

-

• 2" thick insulation

• Natural or vapor LP gas gun style burner with fuel, air mixture adjustment

• Modulating gas valve, safety valves, pressure gauges, and adjustable orifice

• Safety flame monitor, ignition transformer, and airflow switch

-

• Pre-wired electric panel with main disconnect (3-phase, high or low voltage, 50 or 60 cycle)

• All motors with thermo overload protection, TEFC

• Hollow bore gear reducers

• Thermometers

• Tubular construction, carbon steel

• High temperature limit safety switches

• Adjustable pitch vane axial fan

• Frequency drive on each conveyor drive

• Course weave woven wire conveyor belt with roller rack

• V-style bottom air chamber

• Inlet hopper with adjustable product leveling gate

• 2" to 12" of product depth

• Conveyor drive roller with rubber lagging, auger idle pulley

• Standard temperature designs up to 250 degrees Fahrenheit

-

• Product spreaders: Oscillating tube, belt wiper, rotary beater, etc.

• Auto fines clean out systems

• Frequency drives on fan(s)

• Product discharge conveyor or auger

• UL approved electric panel, PLC integration

• Food grade construction (inside, outside, or all)

• Centrifugal fan(s)

• Fine weave conveyor belt (304SS), solid tray conveyor belt, or custom belt

• Product stirring equipment

• Alternate heat sources (steam, oil, biomass, waste, etc.)

• Removed fan and burner systems (fire safety)

• Reverse end conveyor drives with wash down area (CIP)

• Multiple doors (to customer specs, large or small)

• Fan silencers

• Cyclone systems and exhaust fans

• Rotary airlocks

• High temperature applications up to 400 degrees Fahrenheit

• Various burner design packages

• Multiple stages/passes

• Recycle heat options

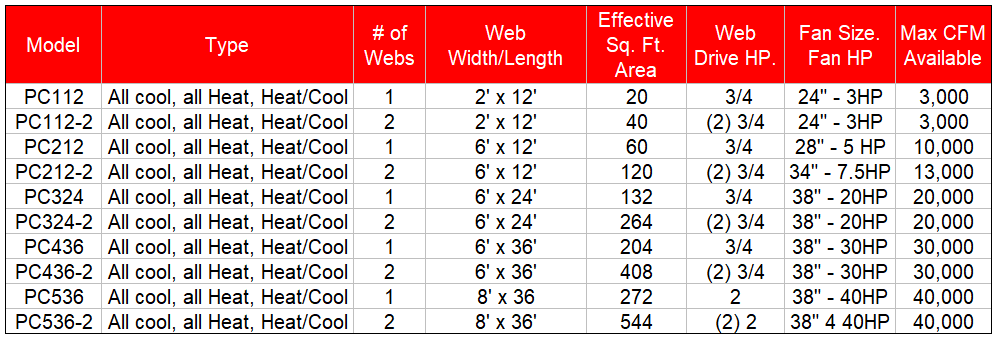

MODEL OPTIONS

100 SERIES

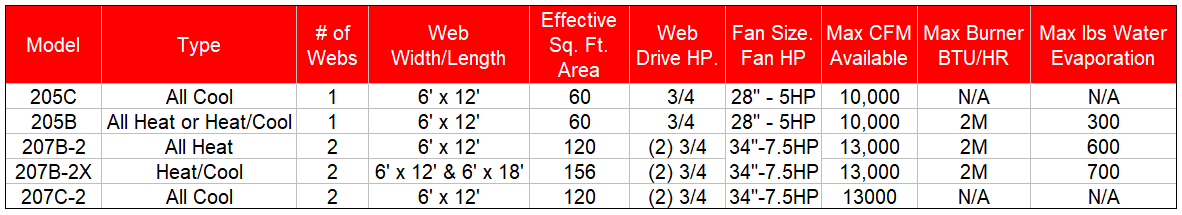

200 SERIES

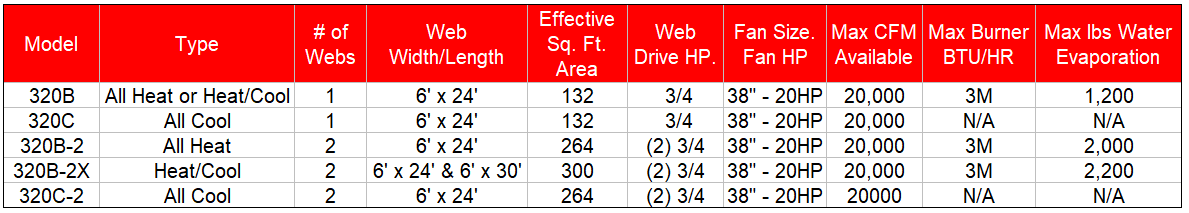

300 SERIES

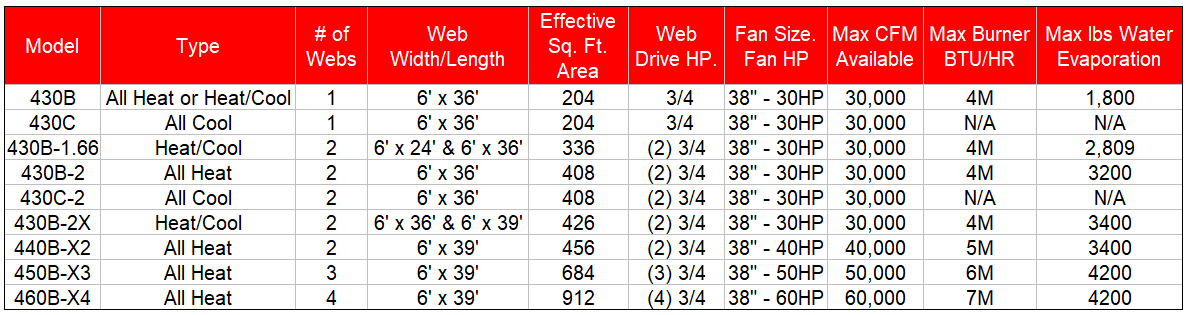

400 SERIES

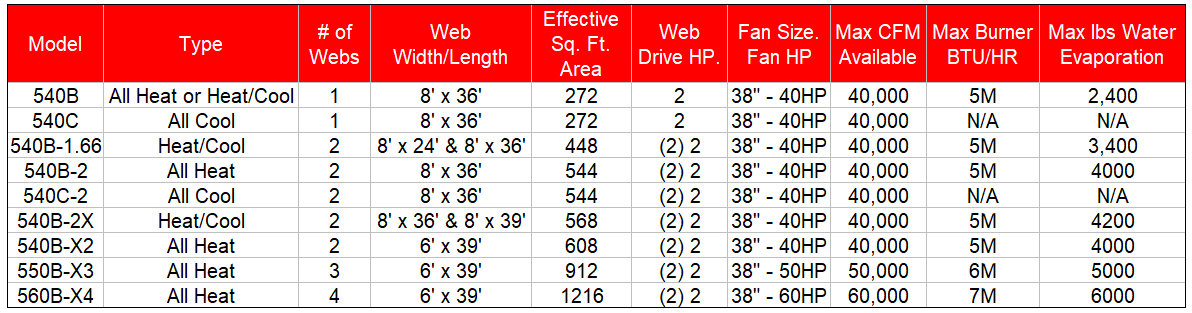

500 SERIES

PC SERIES

CALL OR EMAIL FOR MORE INFO

Phone # (574) 353-7855

Aaron Norris – Sales | aaron@norristhermal.com

Janelle Norris - Parts and service | janelle@norristhermal.com

Cody Johnston - Technical support | cody@norristhermal.com